THE PROBLEM

Losing business to competitors. When production is running at capacity, how can you increase your chances of being able to say “yes” to customers more often? There are two approaches to this problem: internal and external. Both are made easier by applying the right technology.

THE INTERNAL SOLUTION

Operate more efficiently. Producers must control how smoothly their operations are running. When you’re struggling to produce and deliver high volumes of material, lost time can never be made up. You’ll never recover a bad batch of concrete or regain an hour of plant downtime. Any process that causes your company to slow down needs to be eliminated.

PLAN A

There is typically room for improvement in the quote-to-order cycle. Customer pricing and quotes need to be recorded and easily accessible to those responsible for entering orders. Dispatchers must have quick and reliable access to customer data. An integrated customer relationship management (CRM) system keeps data flowing smoothly. Pertinent information should be available on cell phones and tablets via cloud-based business management software, so your employees can handle their day-to-day responsibilities quickly and accurately.

THE EXTERNAL SOLUTION

Redefine your “best” customers. It seems counterintuitive to turn down a potential order. But when you’re struggling to keep up with high demand, you may be spending too much time meeting the demands of the wrong customers. Why prioritize a difficult customer when you already have more business than you can handle?

PLAN B

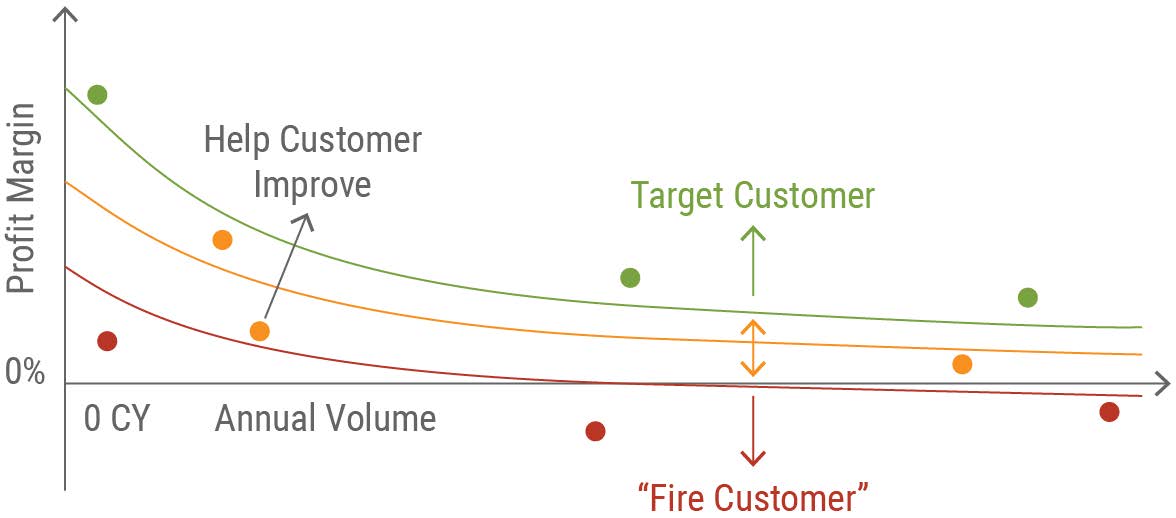

A data-driven approach will clarify who your best customers really are. Invest in an internal review, which will be easier with specialized financial reporting software, to discover and rate customers’ profitability. Critical data includes several order changes; order cancellation rate; late order confirmations; claims and disputes; and, of course, your profit margin on orders compared to the cost of materials and trucking.

Monitor the behavior of your customers, aside from the relationships, and take a hard look at anything that falls outside of your profitability range. Focus your efforts on the customers who consistently make you money. Give less attention to the bottom performers — those who account for your lowest margins or actual money lost — and allow them to take their business to your competitors.

There is generally room for improvement in any part of the ready-mix business process, from improving driver efficiency to equipping your sales force with better tools. Producers who commit to making data-driven decisions will amplify the returns in an up-market, and also soften the blow of the next downturn.